Rebuild

Extend asset life and improve sustainability by rebuilding machinery.

Instead of merely discarding and replacing certain key and expensive machine components, remanufacturing can often breathe new life into equipment. You can enjoy lower maintenance costs, less frequent failures, enhanced reliability, lower total cost of ownership, environmental benefits and more.

Remanufacturing services

Remanufacturing is a major contributing element to reducing the life cycle costs of industrial equipment, giving overall benefits such as:

- Extended operating life of the component

- Reduced maintenance costs

- Enhanced reliability for production up-time and productivity

- Reduced likelihood of failures

- Better maintained condition of replacement stock

- Improved overall asset reliability

- Input for reliability improvements

SKF offers services for the remanufacturing of bearings, gearbox/driveline, and machine tool spindles.

|

Industrial bearing remanufacturing

Through our controlled remanufacturing processes, you can significantly extend the life cycle of your industrial bearings. This reduces costs, lead times and your environmental impact compared to replacing them.

Our bearing remanufacturing network covers most parts of the world and typically includes four types of bearings:

With SKF, you have the assurance that you can get high-quality services, whenever and wherever you need them.

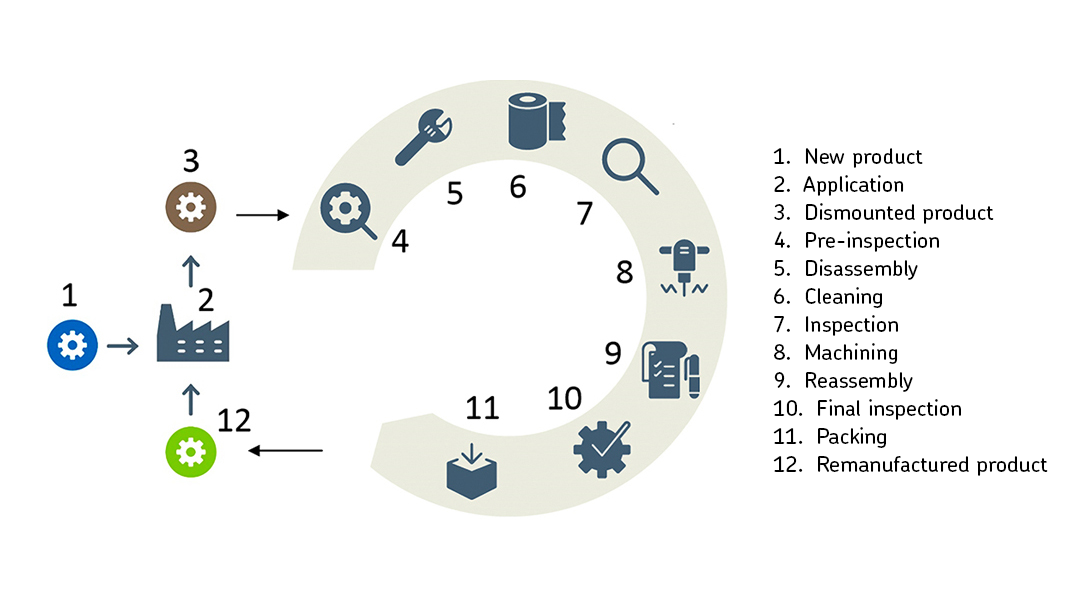

How remanufacturing enables the circular economy

Discover more about our remanufacturing capabilities:

Insights: remanufacturing bearings

A recent article in SKF's Evolution Magazine takes a detailed look into the process of remanufacturing bearings with SKF, and how our wealth of experience and expertise ensures high-quality results.

Driveline upkeep

Our long experience with Rotating Equipment Performance also extends to gearboxes and drivelines, enhancing reliability throughout the gearbox life cycle.

You can leverage a wide range of driveline-focused services depending on your needs, from on-site inspections and upgrades to repairs, reconditioning and maintenance operations.

|

|

Machine tool spindle services

At our machine tool service centres around the world, we ensure thousands of spindles for countless applications are perfectly precise, maximizing their reliability and uptime.

Explore Rotating Equipment Performance further.

There are four more areas where SKF can help you maximize savings and improvements. With different service levels to choose from, you can retain a product-based purchasing approach or evolve to a performance-based one. Either choice can give you access to the latest connected technologies and services without the need for large capital investment.

Assess

Through detailed analysis of your machinery, asset management and processes, we can help minimize unscheduled breakdowns, maximize the effectiveness of your equipment, boost your profitability and improve safety.

Detect

Take a proactive approach with connected technologies, data analysis and visualization, and remote access to SKF expertise. With these key enablers, you can gain powerful insights into your rotating performance.

Maintain

Explore a range of products and services that are not only perfectly suited to your machinery, but that also help you keep pace with technology and comply with environmental and safety requirements.

Solve

Through management of spare parts and lubrication, root cause analysis and application engineering, you can resolve problems and minimize the chances of them re-occurring.

Maintain

Maintain Solve

Solve